|

T2GZ02350 intelligent rolling forming machine is a new type of machine developed by fumin porcelain machinery based on modern rolling forming machine and based on existing production technology and new technology research.It inherited all the advantages of modern rolling machine, and on this basis for new research and development design, more in line with the needs of modern production technology.The equipment has the advantages of high precision, simple operation, convenient maintenance and long service life.

A number of new technologies have been used in the design.The machine is suitable for both male and female die forming.The rolling head can be adjusted up and down, left and right, front and back and Angle.

Feature 1: the rolling head and spindle adopt frequency conversion stepless speed control system, and its speed can be seen in real time.

Feature two: the spindle suction die adopts vacuum generator, low power consumption, free of vacuum pump, no maintenance, no oil change.

Feature 3: the roller head is installed with stepless temperature-controlled heating, and its carbon brush is wear-resistant, long-lived and easy to replace.

Characteristic 4: mainshaft variable frequency brake is maintenance-free.

Feature 5: pneumatic edge cutting system, the use of cemented carbide type scraper, can achieve the blank body edge and inner arc directly formed, reduce the work of the finishing process, and this forming method can greatly reduce the probability of the edge cracking.

Features 6: the molding CAM adopts a five-stage variable frequency stepless speed regulation system, touch screen input can arbitrarily change the roller head down pressure, prepressure, static pressure, rise, stop the speed and time, to maximize the production process requirements of the product.

Features seven: the molding CAM material for 45 steel plate heat treatment production, compared with the traditional cast iron CAM, with high strength, wear resistance, stable operation characteristics, can achieve permanent use.

Feature 8: storage memory system: product production process parameters can be memorized and stored, which is convenient for parameterized management, and can realize process adjustment data. Besides, it does not depend on manual experience, and can be changed at random.

Features 9: the equipment is equipped with the residual mud conveying system, the use of residual mud conveyor belt, the residual mud into the collection box in time, the operator from cleaning the residual mud work, improve the work efficiency, and greatly improve the equipment production environment dirty, messy, poor problems.

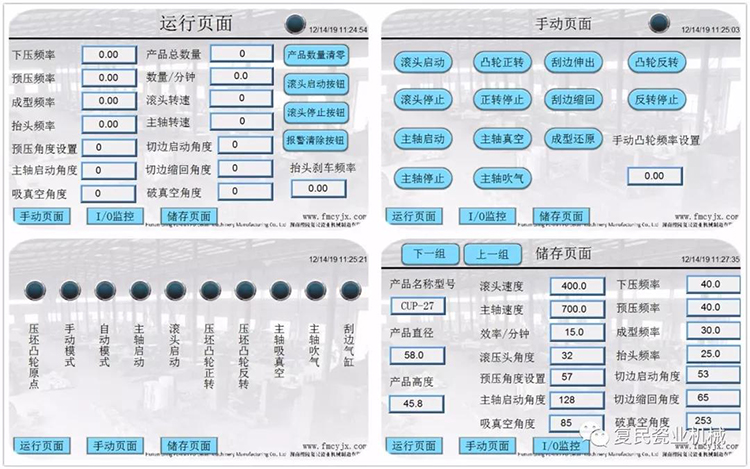

The machine adopts PLC intelligent control system, the man-machine interface operation part is as follows:

Basic technical parameters of equipment

1. Production capacity: 6-14 pieces/min

2. Molding range: diameter: 12 inch and below, height: 180mm and below

|